ABOUT US

Dongguan SENLAN Mold Parts Co., Ltd. was established in

2012 and specializes in precision machining of mold

components, particularly for non-standard customization in

precision packaging molds. With years of industry experience and

technical expertise, we provide efficient and professional mold

parts processing services to global clients.

Core Business

We focus on precision machining of multi-cavity mold components,

including plastic mold cavities, core pins, inserts, movable core

assemblies, and automotive die-casting mold cores and inserts. Our

products are primarily used in precision packaging molds for

industries such as daily-use packaging, cosmetics packaging,

medical consumables and packaging, as well as automotive,

electronics, and automation.

Technical Advantages

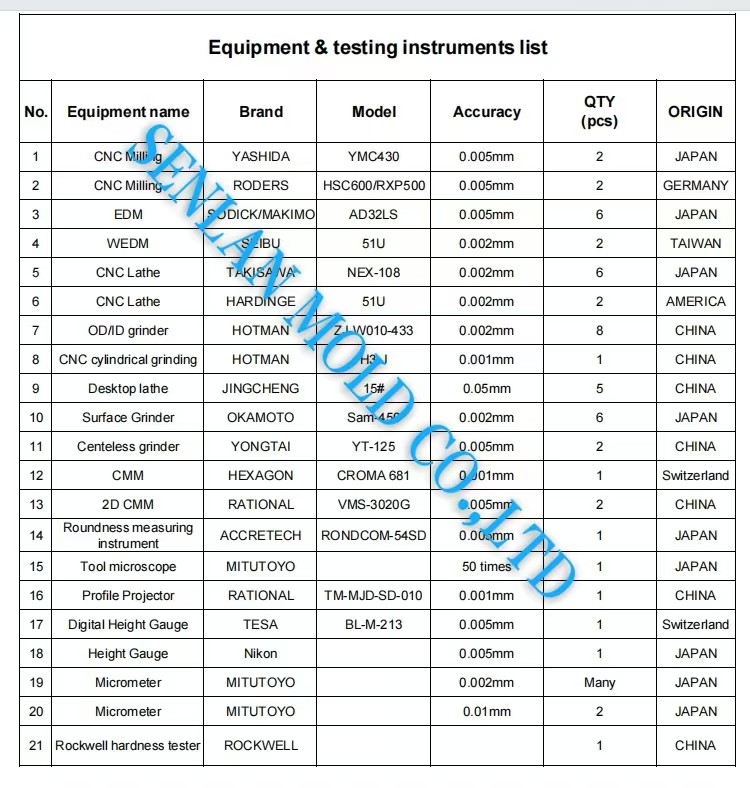

Advanced Equipment: We are equipped with internationally renowned equipment,

including Hardinge CNC lathes, Makino EDM machines, Makino milling

centers, Sodick wire-cutting machines, and a series of precision

grinders, ensuring high-precision machining.

Strict Quality Control: Equipped with Zeiss coordinate measuring machines (CMM) and other

precision inspection tools, we ensure stable performance and

superior quality.

High-Quality Materials and Heat Treatment: We use premium materials from leading brands and ensure that each

material undergoes heat treatment by its original manufacturer,

guaranteeing optimal performance and reliability.

Professional Team: Our management and technical team have over ten years of

experience in plastic and die-casting mold production, offering

customized solutions to meet client needs.

Customer Service

We adhere to the philosophy of "Quality First, Honest Service,"

committed to providing high-quality products and excellent service.

Whether it's complex multi-cavity mold components or custom parts

with special requirements, we deliver precise machining to meet the

high standards of precision plastic molds.

Future Vision

SENLAN will continue to focus on technological innovation and

quality improvement, working closely with global clients to drive

the advancement of the mold industry.